Day 2 w2

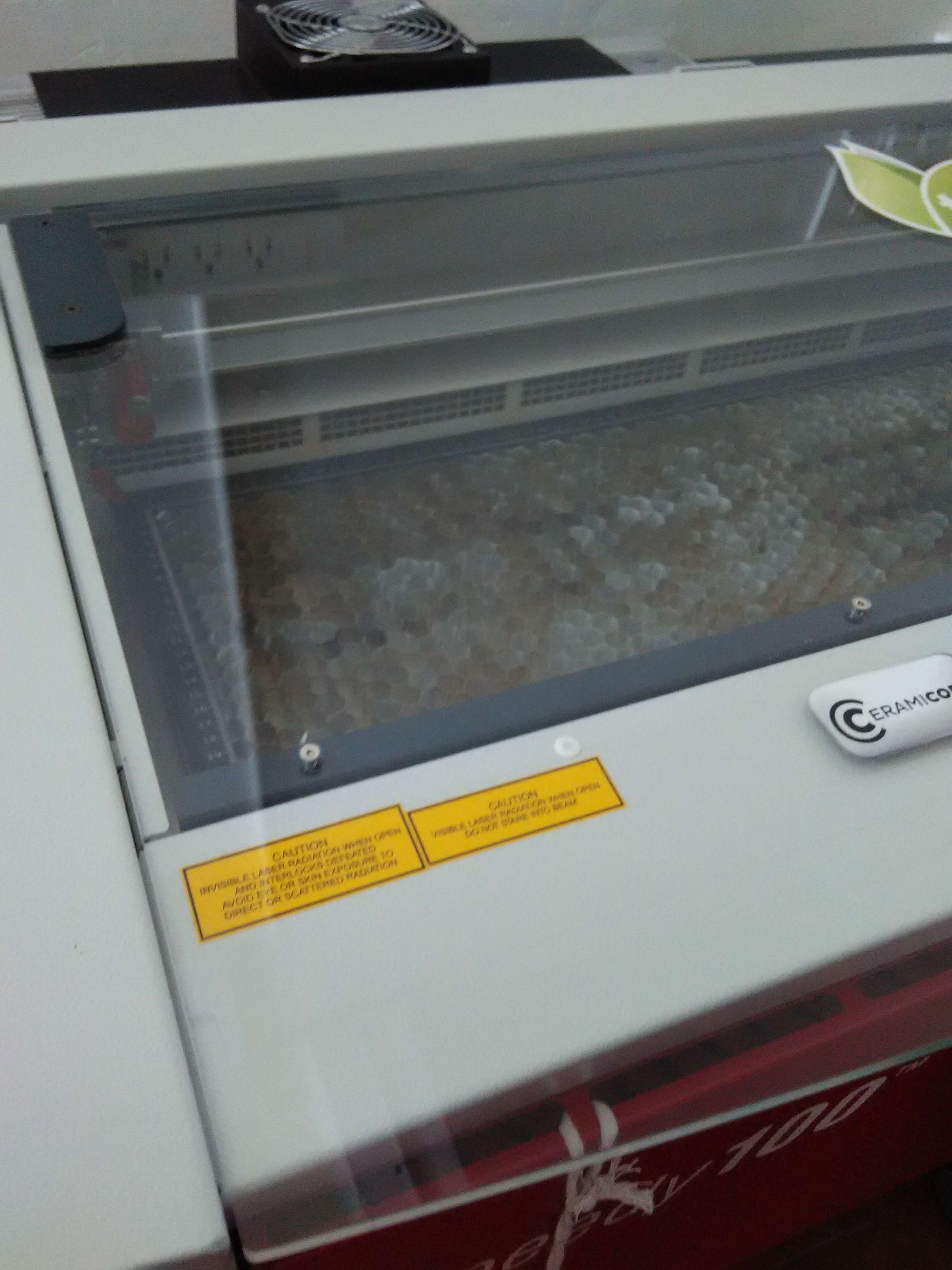

Laser in our fablab is a trotec speedy 100 with that we have an atmos exhaust filter from trotec. Here's the laser machine and our super cool prefab guide and fabguru Francisco explaining about the filter system.

Laser in our fablab is a trotec speedy 100 with that we have an atmos exhaust filter from trotec. Here's the laser machine and our super cool prefab guide and fabguru Francisco explaining about the filter system.

Polycarbonate lid and Atmos Exhaust Filter system

Filter parameters

Things to watch out for

Exhaust filter should be on. Fablab is a closed space here and toxic fumes from burning acrylic and other plastic might soon fill the space and can cause headaches and other problems.

Curvature of material

It is better that the bulge is in the corners so that the corners can be pushed to flat and taped. If the material bulges in the middle it cant be taped down in the middle to make it flat.

Focusing the machine. It is very important to focus the machine every time you load a material or start the job in a different area.

When dealing with cardboard it is better to increase power and cut faster. If less power and less speed is employed the cardboard can catch fire.

We tried different setting for cutting the cardboard the following combination were tried and final setting arrived at after some trials. The 4mm cardboard which we were using had to be cut just enough to be easily removed we started with power 40 and speed 3 frequency of laser pulses - 5000Hz . The plan was to keep speed and frequency constant and change the power untill a good cut is got.

trials

P(power) 40 S(speed) 3- didnt cut through

P 50 S3 - Didnt cut through

P 60 s 3 - Partial cut but still tricky to remove

P 70 S 3 - Material cut all the way and came out with slight force but it could be improved

P75 S3 - Material cut all the way through and easily removable.

Setting for good engraving and good cutting for every material and each thickness has to arrived like this. You keep either speed or power constant and change the other parameter and make tests until you reach a setting giving you desired effect. All these things should be noted down and so that it is helpful for later use and in case the machine is not behaving properly it can be used to debug. It makes it easier to identify a problem and allow machine to be run optimally.

Thickness of line are not filled. If you add a thick line the all the thickness is not cut. A line is always cut like a line and thinker line like a block wont be cut like block. Use line of thickness 0.01 mm.

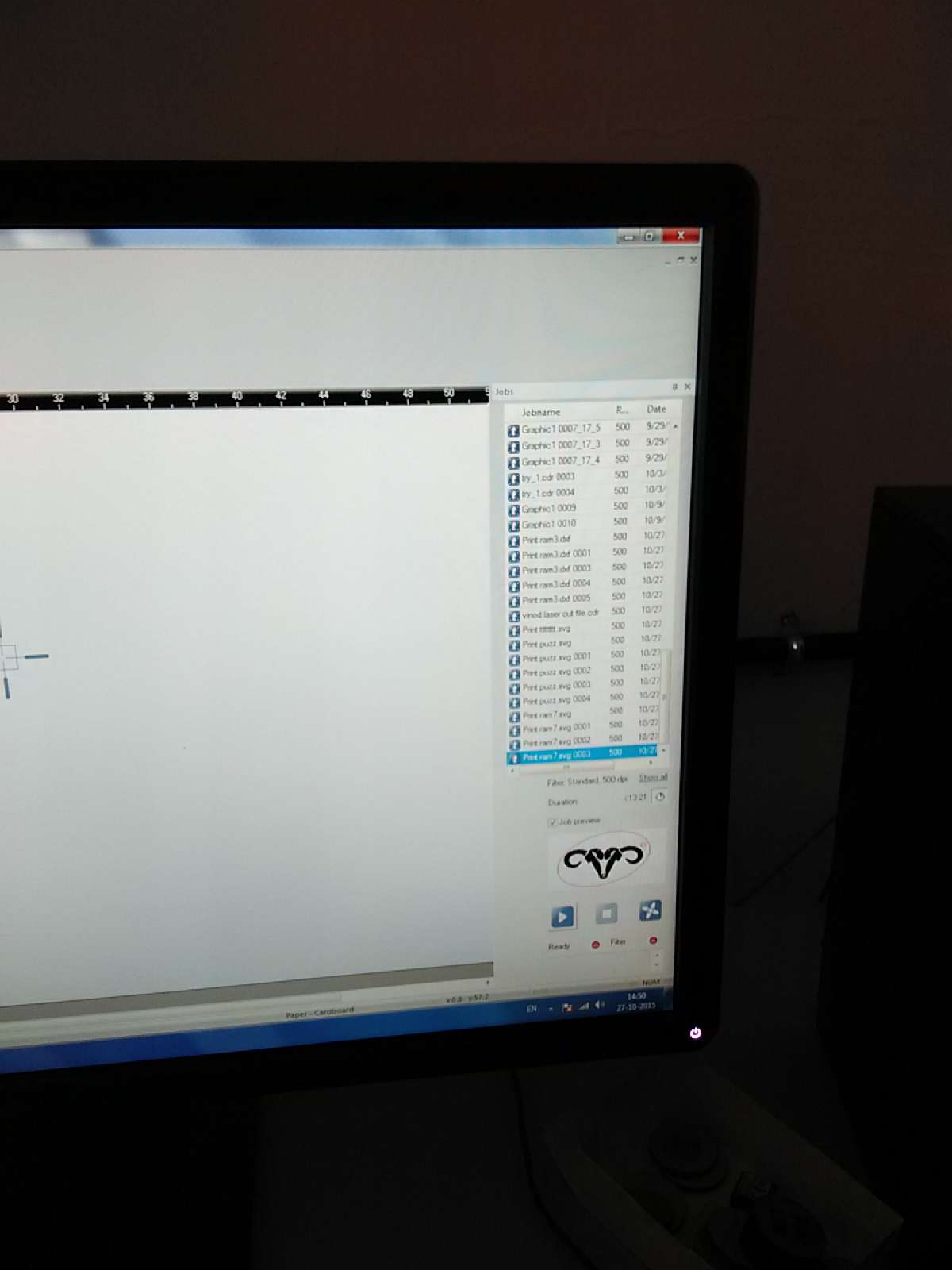

Preview of the job in the bottom right corner.

Final product. A keychain with laser engraved ram.