Vinyl cutting

Used to make sticker and best use is to make PCB that are flexible. Can cut copper, epoxy and vinyl sheets.

Loading the material

Use this lever to release or secure the vinyl.

Materials

should be between the two translucent patches as shown in the picture.

These have rough surface in order to grip the papaer better. The wheels

should secure the paper when the lever is engaged. The paper cant be

secured in other places or any paper smaller than the length between two

translucent rough patches.

Allign it: Parrallel to the scores provided in the machine.

Settings should remain as the following.

Pen force +2 always

Set different force and other setting from fab modules.

Set different force and other setting from fab modules.

The patch of

127

441

Do a Test cut to check if it is working good. It cuts a square inside a circle and the criteria that the vinyl cutter is good condition is that the inner square should remain stuck to the base but the exterior circle with square hole should come off

The Test button needs to be long pressed for around 500 ms

Problem

The circle came out with the square so the cutting is in complete.

We tried the following to troubleshoot

1. Blade length increased.

This didnt help and increasing the blade length too much is not recommended and it actually ponts to different problem.

2. We removed the blade and inspected it. Debris were found, We cleaned it but these debris cant cause a severe problem as not cutting. It can cause problem in free rotation of the blade and improper cut. We were getting clean lines but not deep enough cut.

127

441

Do a Test cut to check if it is working good. It cuts a square inside a circle and the criteria that the vinyl cutter is good condition is that the inner square should remain stuck to the base but the exterior circle with square hole should come off

The Test button needs to be long pressed for around 500 ms

Problem

The circle came out with the square so the cutting is in complete.

We tried the following to troubleshoot

1. Blade length increased.

This didnt help and increasing the blade length too much is not recommended and it actually ponts to different problem.

2. We removed the blade and inspected it. Debris were found, We cleaned it but these debris cant cause a severe problem as not cutting. It can cause problem in free rotation of the blade and improper cut. We were getting clean lines but not deep enough cut.

3. Inspection of the blade tip.

We inspected the blades under a microscope camera and compared a brand new blade with the used blade. The problem was evident. The edge was blunt and edges eroded.

Ideal length of the blade length looks like this.

The final test cut looks good.

Setting origin

Move the vinyl to desired location. Usually bottom corner of the paper or any free space or space good enough for your piece. Origin has to be set now. To set origin long press Origin button.

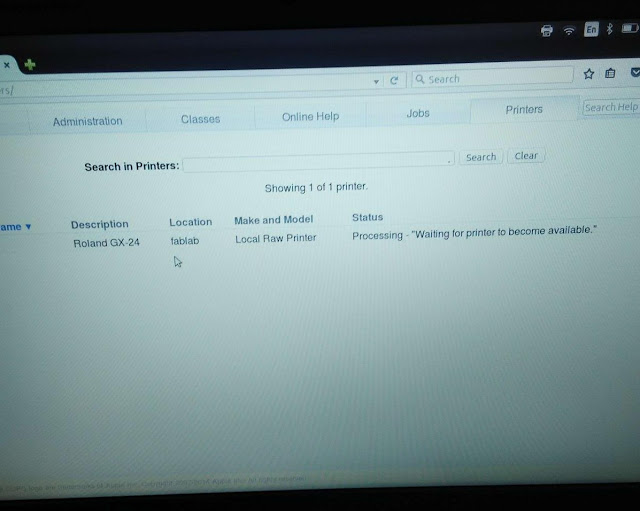

Connect the vinyl cutter to the computer and open http://localhost:631/ in web browser to access the CUPS.

CUPS is the standards-based, open source printing system developed by Apple Inc. for OS® X and other UNIX®-like operating systems.

Follow these steps to add and configure roland vinyl cutter to ubuntu.

Adminstration-> Add printer->Roland GX-24

Name it as "vinyl". Do not vary these.

Choose RAW for drivers. This means that the printer is going to directly controlled by the computer. The software that does it is the fab modules and through this we bypass the drivers installation and configuration etc.

In the "Printer tab"

Work with the settings from top to botttom and letf to right.

Top most is - Type of material

Then Load png

Make path,

Make camm

and Send it.

Sometimes the printer doesn't run from the fabmodules

The following troubleshooting can be attempted and were attempted while using the vnyl cutter.

Go to CUPS

Check jobs in cups

Cancel jobs

Go to printer tab it should b ready and not idle

Next

Pause and resume printer

Unplug and replug- Worked best for us

Name it as "vinyl". Do not vary these.

Choose RAW for drivers. This means that the printer is going to directly controlled by the computer. The software that does it is the fab modules and through this we bypass the drivers installation and configuration etc.

In the "Printer tab"

Work with the settings from top to botttom and letf to right.

Top most is - Type of material

Then Load png

Make path,

Make camm

and Send it.

Sometimes the printer doesn't run from the fabmodules

Go to CUPS

Check jobs in cups

Cancel jobs

Go to printer tab it should b ready and not idle

Next

Pause and resume printer

Unplug and replug- Worked best for us

Things to note. Even though the vinyl machine automatically measures the length of the roll. It leaves about 2 inches of the material uncut. This is because the sensor that measures the sheet is placed farther away from the actually cutting area. It doesnt estimate the distance between the sensor and the cutting area and it is not considered. So you might feel like you have enough vinyl to be used but make sure it can be cut with 2 -3 inches away from the end of the sheet.

Final product.