Frank gave us introduction to antimony. And we proceeded print out few things in 3d printer.

Antimony

Antimony is a great software and very easy for beginners in 3d modeling. Once you get tuned to antimony you'll probably not require any other 3d modeling software for much of 3d modeling needs. I'll note down few features of antimony although you'll relate to it if you are a involved in 3d modeling or a mechanical engineer or mathematician.

Features

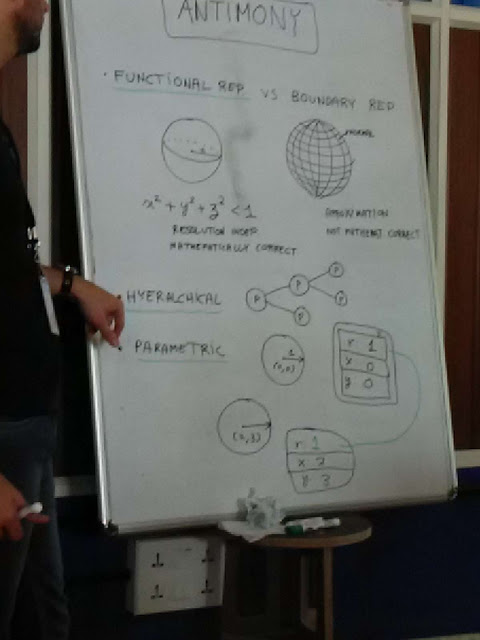

-Functional representation as opposed to boundary representation. Most professional softwares use boundary representation. It means that an object is defied by a boundary and not as equation. There are a few specialized softwares which have functional representation and is needed for specific purposes only. OpenSCAD is one such software.

- Hierarchical system to manage 3d modeling. This is a very handy feature. Be it any 3d modeling software you create a desired shape in steps and adding or deleting features. This allows you to go back to a previous step and change something. This change is reflected in final model also.

- Parametric- Means each feature has features that can be manipulated by certain parameters. A cylinder will have the position variables, length and radius as parameter. By changing these parameters you can get a cyclinder you wish for.

There might not be any software that provide all these advanced features in a package and that too for free. I feel antimony offers the most freedom while 3d modeling.

On the side note you can't create features which is freehand. You don't draw a curve which you feel is right. You have to convert your desired curve to an equation of set of points that can be used to create a curve in antimony.

The user interaction needs to improved a lot though. Wish they had a commandline feature like in autocad. It is not designed for speed for now. You can output in either heightmap png or stl, I need at least dxf to be output for it be decently useful for me. It is still designed to be used for fablab and has scope for improvement for needs of general public.

I am used to solidworks and thats a standard software most mechanical engineers and engineering 3d modelers are aware of. Switching to antimony will require me to change quite a bit of my thinking but it has a huge potential once you get used to the thought process of antimony. I need it to be more stable if I want to use it for my professional works.

3D printing.

We tried to look for things to print that would be useful in the lab. There are many .stl files for printing available at thingiverse.com which can be downloaded. I designed a filament clip or filament organiser and tried to print it n see if it works. We used cura to generate the gcode for the ultimaker and printed it at

0.2 mm layer height

50mm/s speed

1.2 mm wall thickness

20% fill density

Find files at

https://www.dropbox.com/s/6qur0fosqty113r/filahold.SLDPRT?dl=0

https://www.dropbox.com/s/n2g8x7t14ntbjwk/filahold.STL?dl=0

It didnt work as expected. I used 2.75+0.5% x 2.75(to account for contraction in the plastic after cooling). The filament Dia turned out to be 2.85 and I think I need to add a little clearance also and then finally account for contraction in the part. The part also turned out to be too rigid for the filament to clip into the open loop. So it has to be made thinner, wider or long such that it can flex to accommodate the filament and hold it in place.

Antimony

Antimony is a great software and very easy for beginners in 3d modeling. Once you get tuned to antimony you'll probably not require any other 3d modeling software for much of 3d modeling needs. I'll note down few features of antimony although you'll relate to it if you are a involved in 3d modeling or a mechanical engineer or mathematician.

Features

-Functional representation as opposed to boundary representation. Most professional softwares use boundary representation. It means that an object is defied by a boundary and not as equation. There are a few specialized softwares which have functional representation and is needed for specific purposes only. OpenSCAD is one such software.

- Hierarchical system to manage 3d modeling. This is a very handy feature. Be it any 3d modeling software you create a desired shape in steps and adding or deleting features. This allows you to go back to a previous step and change something. This change is reflected in final model also.

- Parametric- Means each feature has features that can be manipulated by certain parameters. A cylinder will have the position variables, length and radius as parameter. By changing these parameters you can get a cyclinder you wish for.

There might not be any software that provide all these advanced features in a package and that too for free. I feel antimony offers the most freedom while 3d modeling.

On the side note you can't create features which is freehand. You don't draw a curve which you feel is right. You have to convert your desired curve to an equation of set of points that can be used to create a curve in antimony.

The user interaction needs to improved a lot though. Wish they had a commandline feature like in autocad. It is not designed for speed for now. You can output in either heightmap png or stl, I need at least dxf to be output for it be decently useful for me. It is still designed to be used for fablab and has scope for improvement for needs of general public.

I am used to solidworks and thats a standard software most mechanical engineers and engineering 3d modelers are aware of. Switching to antimony will require me to change quite a bit of my thinking but it has a huge potential once you get used to the thought process of antimony. I need it to be more stable if I want to use it for my professional works.

3D printing.

We tried to look for things to print that would be useful in the lab. There are many .stl files for printing available at thingiverse.com which can be downloaded. I designed a filament clip or filament organiser and tried to print it n see if it works. We used cura to generate the gcode for the ultimaker and printed it at

0.2 mm layer height

50mm/s speed

1.2 mm wall thickness

20% fill density

Find files at

https://www.dropbox.com/s/6qur0fosqty113r/filahold.SLDPRT?dl=0

https://www.dropbox.com/s/n2g8x7t14ntbjwk/filahold.STL?dl=0

It didnt work as expected. I used 2.75+0.5% x 2.75(to account for contraction in the plastic after cooling). The filament Dia turned out to be 2.85 and I think I need to add a little clearance also and then finally account for contraction in the part. The part also turned out to be too rigid for the filament to clip into the open loop. So it has to be made thinner, wider or long such that it can flex to accommodate the filament and hold it in place.