Final project discussion, Fabduino.

We are going to put use all the knowledge we gained through the weeks before and try to create a product using fablab facilities ad techniques.

Luciano is going to be our facilitator for this week for this process.

Luciano is product designer by profession and he introduced us to design thinking concepts and process.

We will be designing a product that is going to be such that it can't be

done easily by any other means and is going to fully capitalize on

Searching for perfection spiral process: the prduct that comes out is going to be minimum viable product at first and the idea is to try to perfect it more and more, this is the spiral development of product. We aim a being Capable of doing something rather than gain full mastery in anything. None here would be aiming at becoming a master is mechanical design, fluid dynamics or art. But we can use elements in these fields to build our prduct.

The design thinking process: Here is a way to start a design. We try to answer relevant question to get answer as the criteria for design. Below is one the ways we can do that

Ask, imagine, plan, create improve cycle

Ask- identifying a need, problem statement think of scope.

Imagine : we use brainstorming and divergent thinking to generate ideas. Try to think from different angles, breakdown problem to component problems.

Plan : we think of how to solve. The identified problems or component problems.

Create : involves making the prototype. Improve :involves test and iterations.

Design brief

Design brief is another way that helps designers arrive at an design criteria. We answer the following question in a design brief

What, Who, Why, How and When

What - product description, problem statement. The product I want to design is an ear phone organizer.

-Size-40 to 50 mm

-Material- smooth and easy to handle

-Weight- lesser the better

-Strength - stong enough to take the compressive load when my pant might be pressed against my leg.

-Time - In a weeks time

Who - Who is it for, Age, Gender, etc. The product I am going to design is for myself So I will have to think of only satisfying my needs here.

Why- The purpose is to allow me to store my earphones in my pocket and avoids tangle and damage.

How- 3 printer, laser, Shopbot or molding and casting can be used

When- In a week's time

Solution analysis

We think of solutions that meet the criteria generated from the above exercises to understand the design needs. I locked on to a spool like mechanism that be enclosed and by spinning the spool the earphone wire can be wound.

Risks and benefits - benefit is that this design protects and organizes the earphone and it's small enough to fit into my pocket.

risk- the product I am thinking requires a sliding mechanism, I need to design a very good fabricating way for this mechanism. it might turn out to be a huge task, fine tuning and eating all dimensions right and for it to be

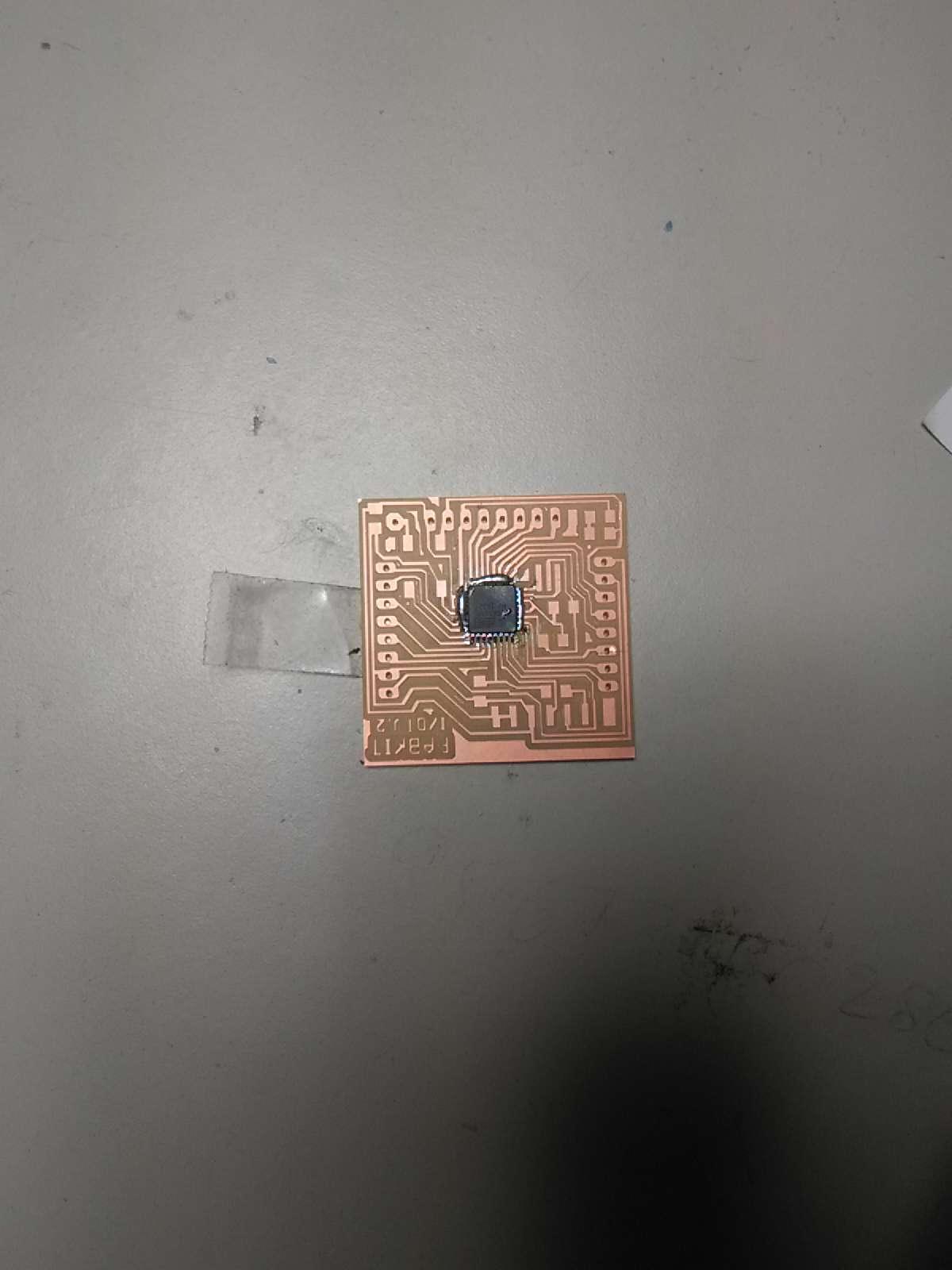

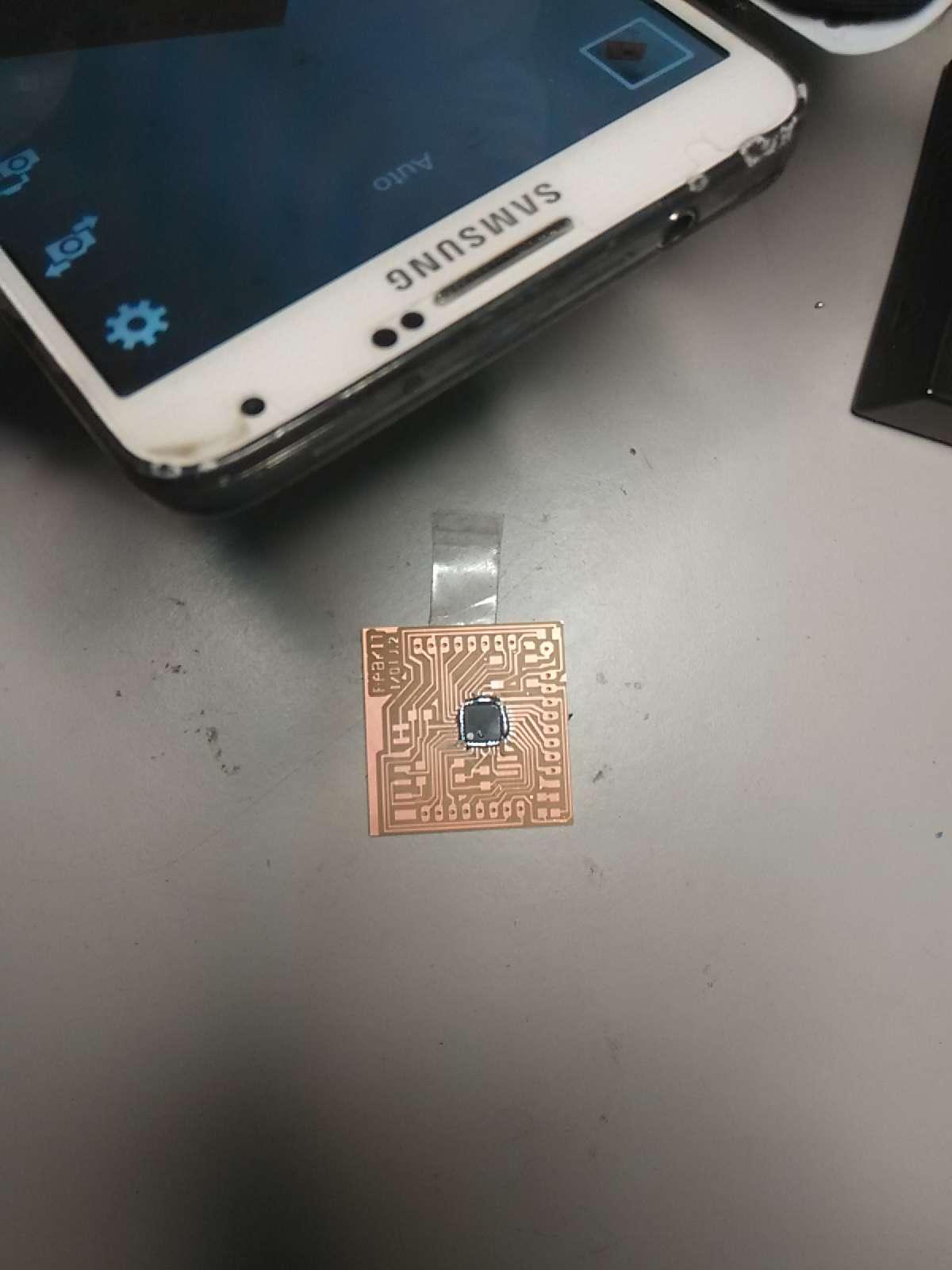

Fabduino

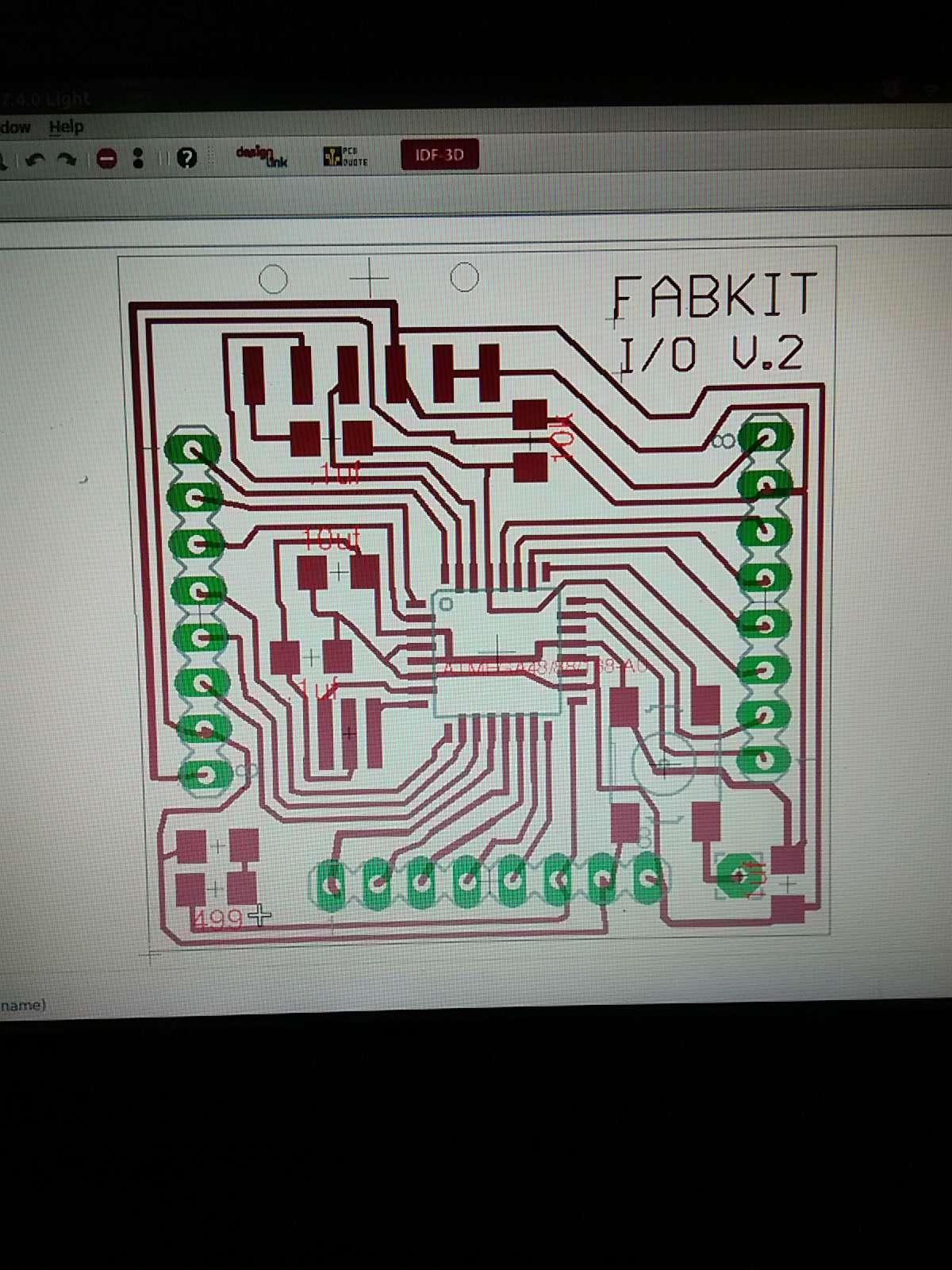

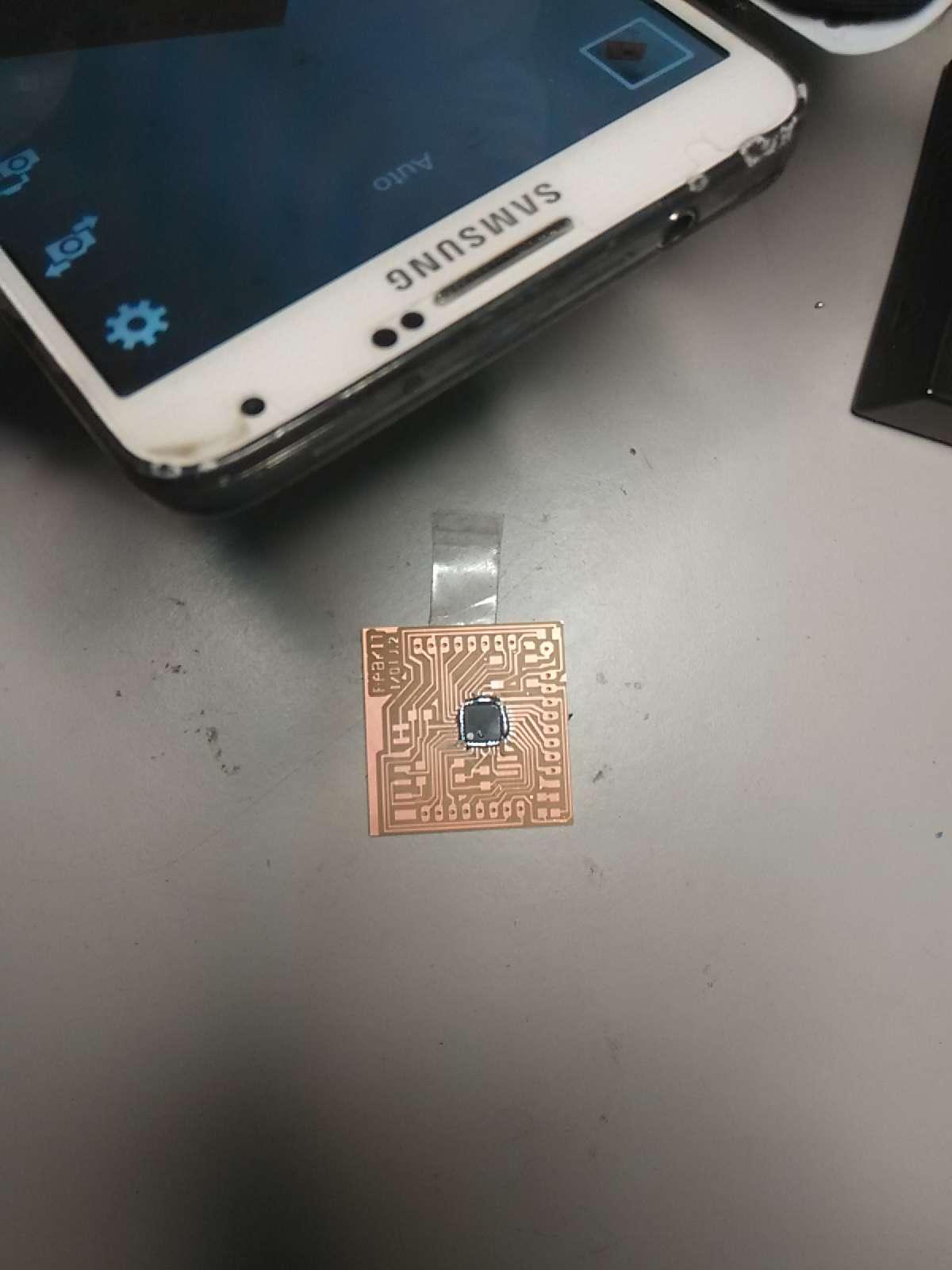

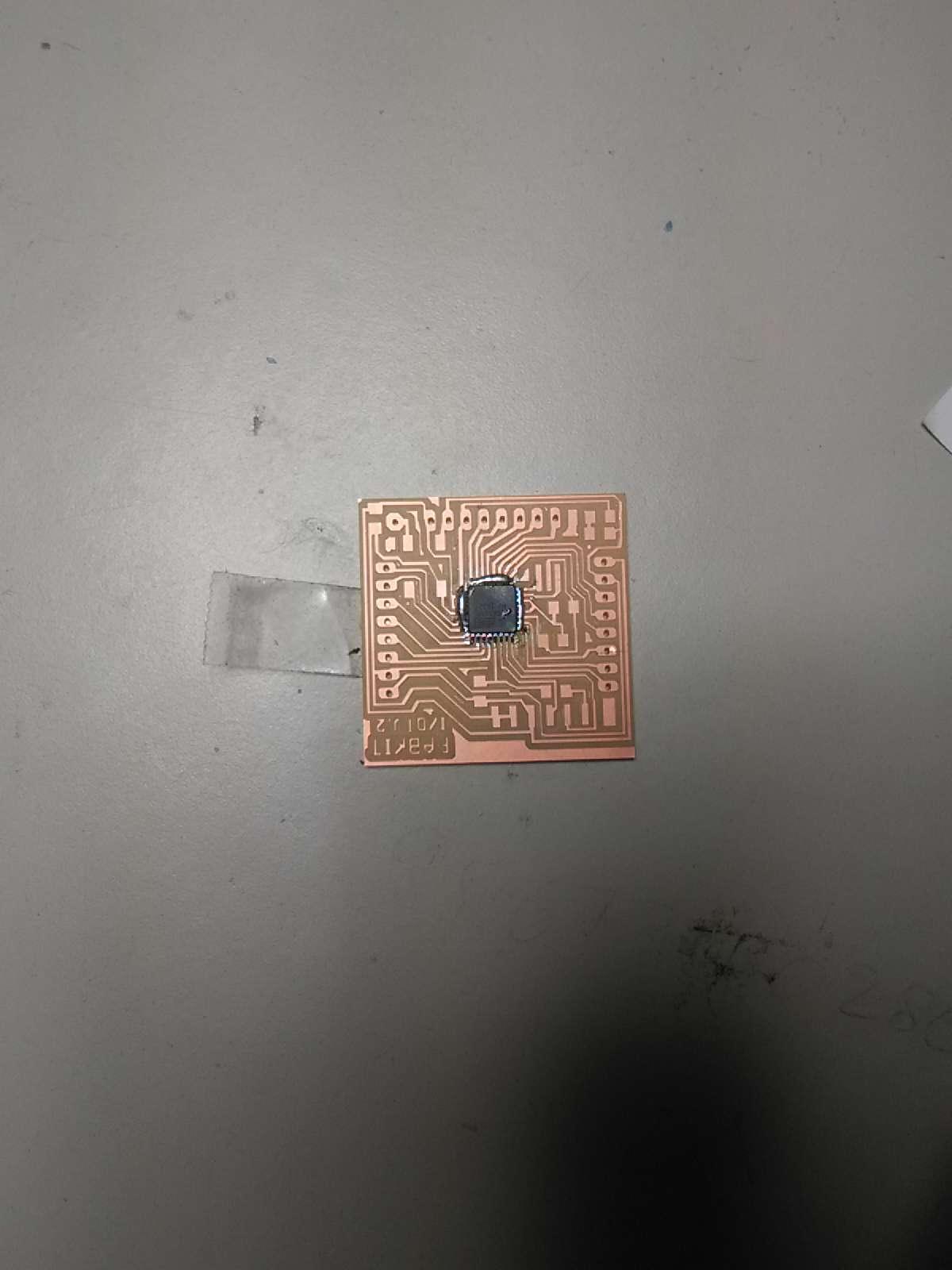

We tried to fabricate a Fabduino. Fabduino consists of atmel controller that can be programmed. It has far more pins, data storage than the attiny controller allowing us more freedom in coding and inputs and outputs. We downloaded the png for fabricating from the following links

fab.cba.mit.edu/content/projects/fabkit/

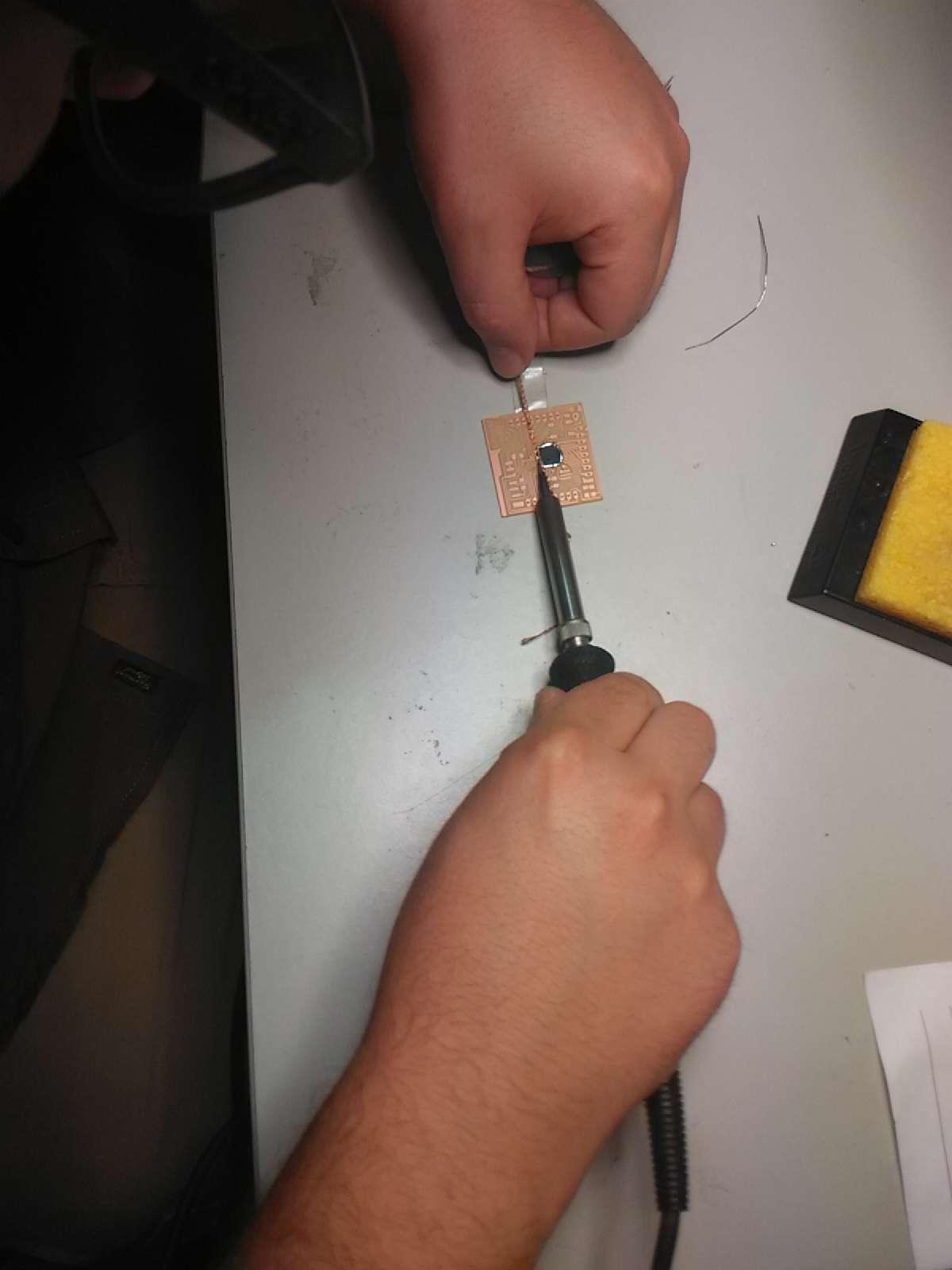

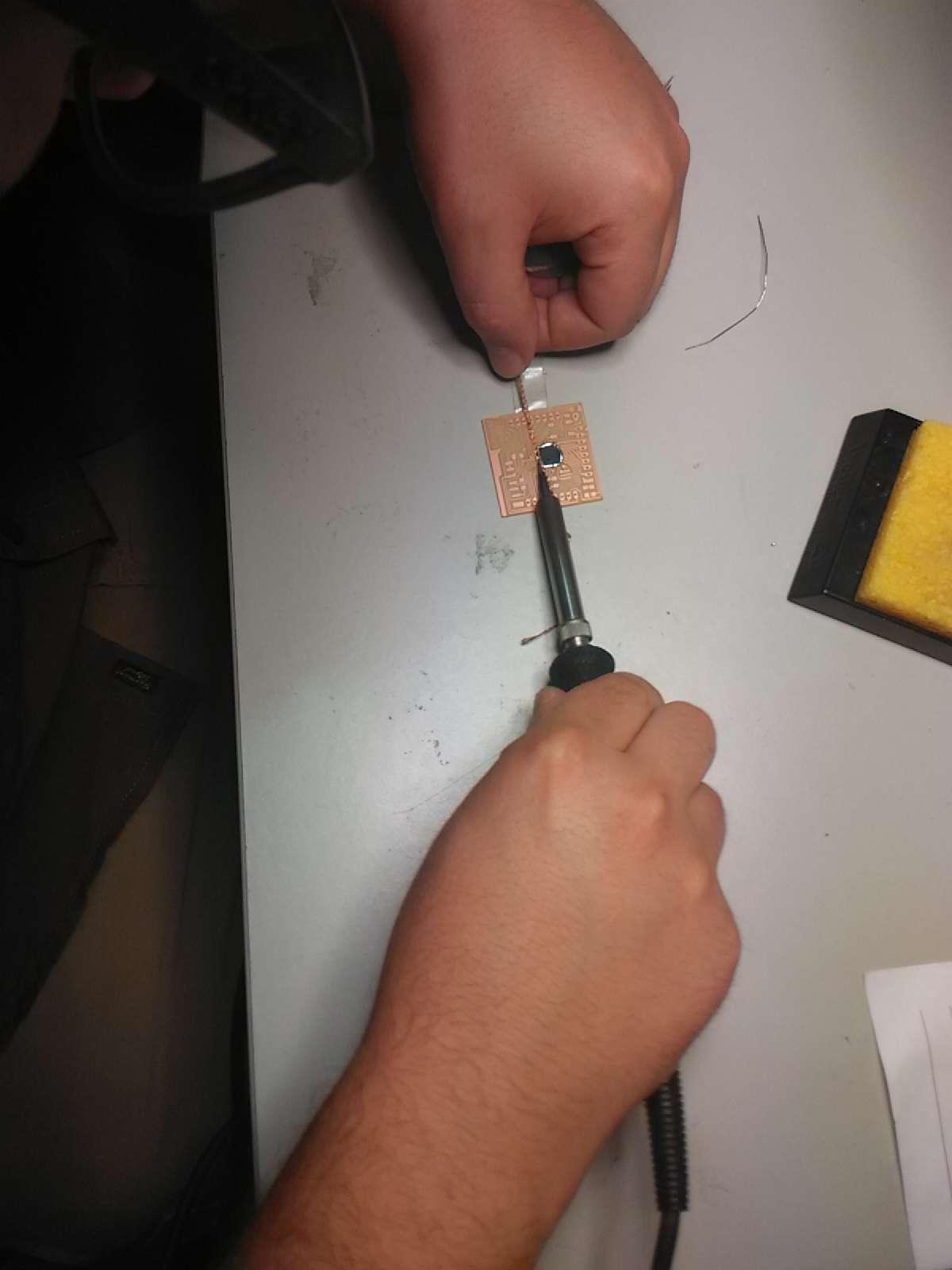

Soldering atmel microcontroller

What's different : as compared to attiny the atmel microcontroller has more leads and smaller gap between the lead and smaller leads and traces. It also accommodates holes so you'll have to download the holes png also. The png given by the site for holes is an inverted image, make sure you use invert function to set this right While milling. Use 1/32 bit to mill holes, same as outline. And make sure you mill the holes before milling the outline.

How?

We secure the microcontroller similar to attiny, by soldering two diagonals corners first.

Next instead of trying to solder each and every one to corresponding trace, we solder all pins together into one mass of lead on each of the 4 sides of the microcontroller.

We are going to put use all the knowledge we gained through the weeks before and try to create a product using fablab facilities ad techniques.

Luciano is going to be our facilitator for this week for this process.

Luciano is product designer by profession and he introduced us to design thinking concepts and process.

fablab concept of personal fabrication. I came up with ideas that is going to solve my problems. The ideas were

1. To print a skin to my mouse. My mouse is smaller than what I feel

ideal holding and the scroll button is hard to press on. Since I am a

product designer as well and work with solidworks and softwares as such,

this feature is extremely important to me.

I might drop this idea. I will be design to fix an imperfect design or

try to model it for my need. I wont be doing any new things here and an

easier solution would be to buy a mouse that fits me better. The mouse

itself is easily available.

2. Laptop charger cable lock. My charger has become loose overtime and

the press fit locking provided by the plug itself has worn out and it

comes of easily. I want to create a product that allows me to lock the

plug in place as long as I need it.

Again since here I'm trying to fix a design issue on already existing

design Luciano suggested this might not be great to work on for my

project.

3. Ear phone organizer- I want to design an ear phone organizer in order

to avoid tangle and extend life of my ear phones by protecting against

damage while making it easier to be placed in my pocket.

Although many earphone organiser are available out there they don't meet

my criteria. The ear buds usually hang out of a spool like object and

while placing it in my pocket the ear buds might get hooked to the

fabric and over time get damaged. I dont want a case also because I want

to quickly wind my earphone on a spool and keep it in my pocket. What I

am looking for is spool like things that also protects my earbuds from

getting tangled with the fabric of my pocket.

I chose this product to pursue since I am going to pursue new design criteria and going to start from scratch.

Searching for perfection spiral process: the prduct that comes out is going to be minimum viable product at first and the idea is to try to perfect it more and more, this is the spiral development of product. We aim a being Capable of doing something rather than gain full mastery in anything. None here would be aiming at becoming a master is mechanical design, fluid dynamics or art. But we can use elements in these fields to build our prduct.

The design thinking process: Here is a way to start a design. We try to answer relevant question to get answer as the criteria for design. Below is one the ways we can do that

Ask, imagine, plan, create improve cycle

Ask- identifying a need, problem statement think of scope.

Imagine : we use brainstorming and divergent thinking to generate ideas. Try to think from different angles, breakdown problem to component problems.

Plan : we think of how to solve. The identified problems or component problems.

Create : involves making the prototype. Improve :involves test and iterations.

After this step we again go to ask, and we try to improve definition of the

problem through experience of prototyping and continue the cycle till we

reach desired product.

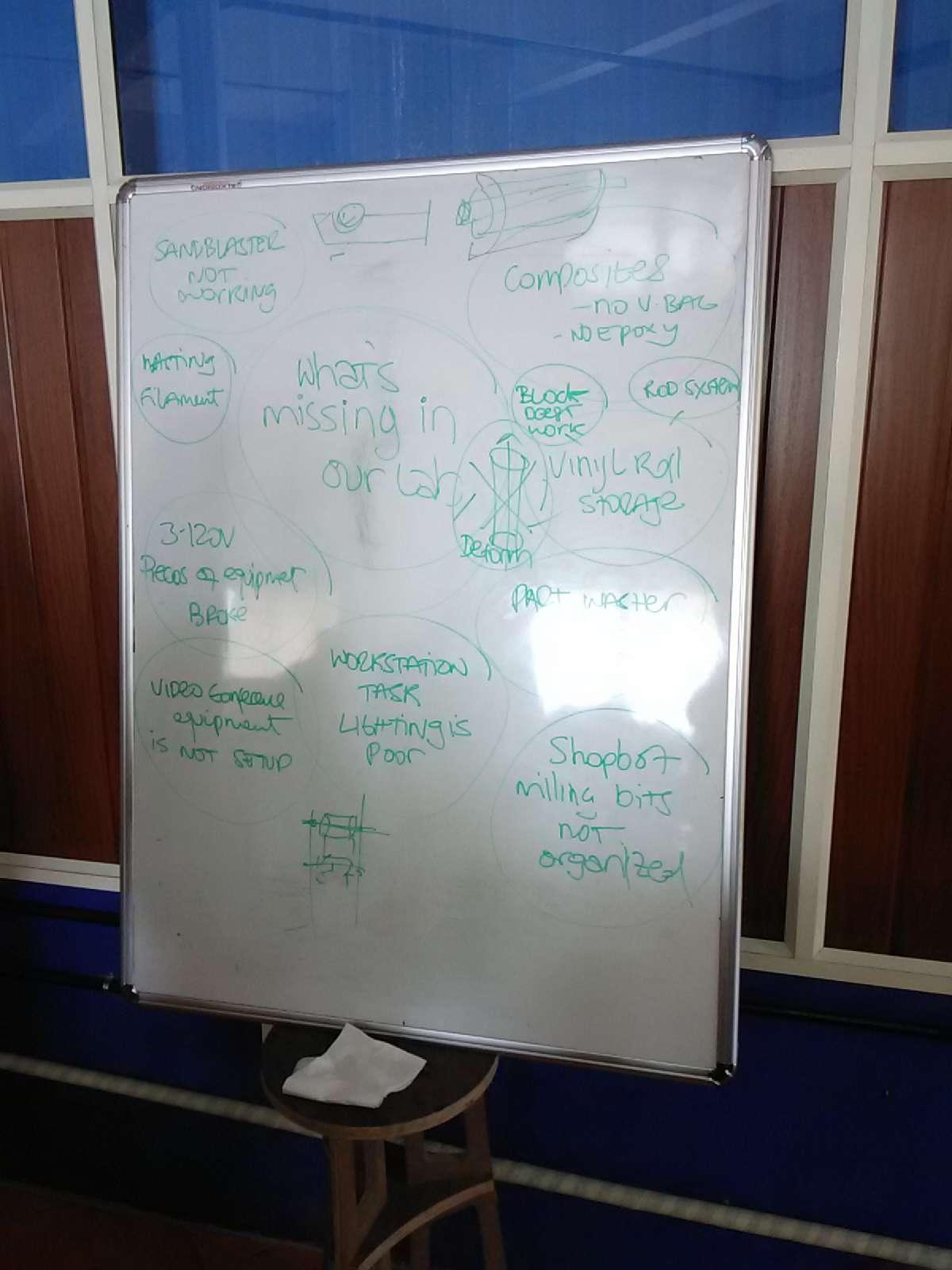

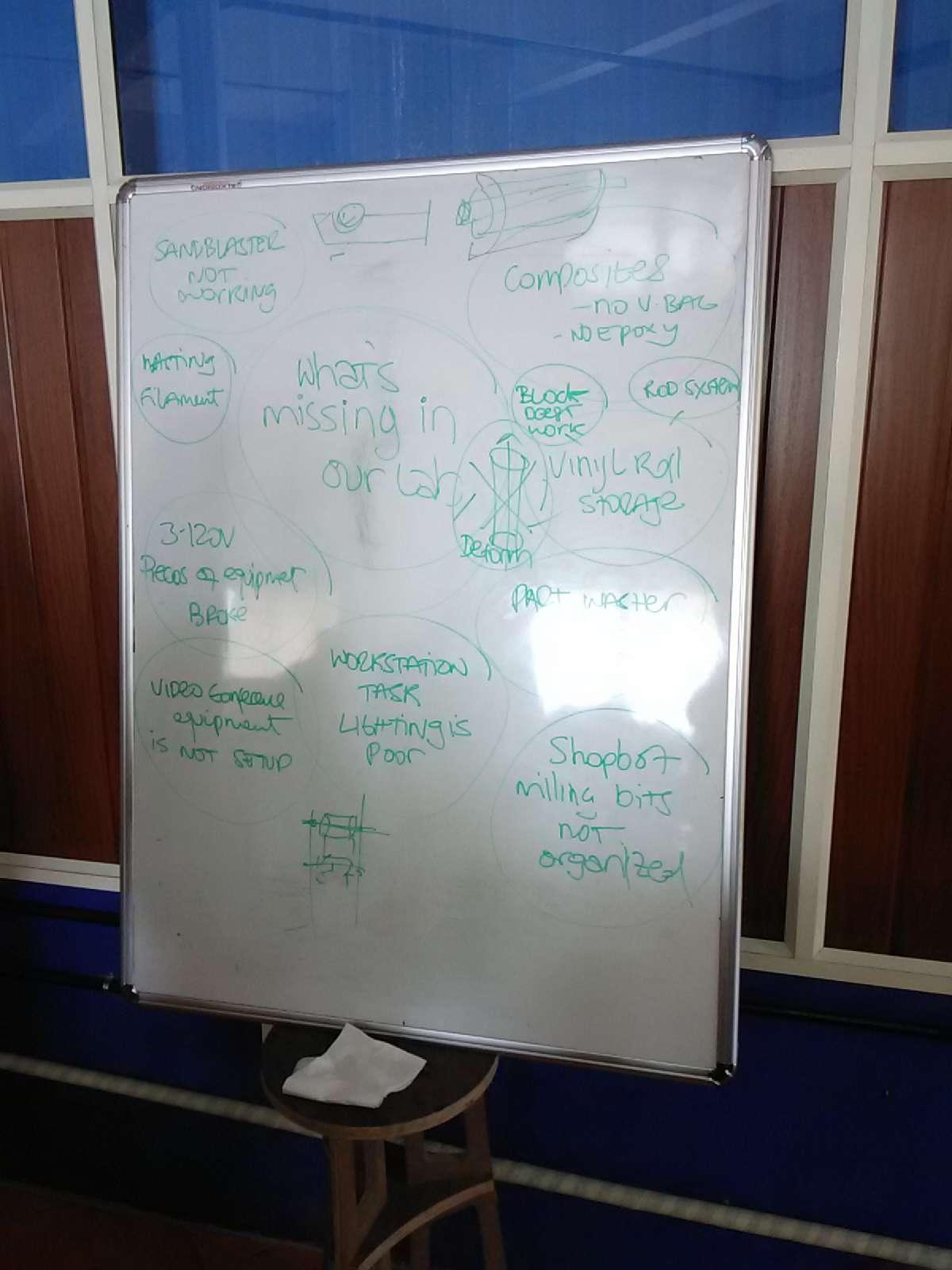

We listed down the things our lab needs as an exercise to brainstorm. We discussed shortly over each problem.

Design brief

Design brief is another way that helps designers arrive at an design criteria. We answer the following question in a design brief

What, Who, Why, How and When

What - product description, problem statement. The product I want to design is an ear phone organizer.

-Size-40 to 50 mm

-Material- smooth and easy to handle

-Weight- lesser the better

-Strength - stong enough to take the compressive load when my pant might be pressed against my leg.

-Time - In a weeks time

Who - Who is it for, Age, Gender, etc. The product I am going to design is for myself So I will have to think of only satisfying my needs here.

Why- The purpose is to allow me to store my earphones in my pocket and avoids tangle and damage.

How- 3 printer, laser, Shopbot or molding and casting can be used

When- In a week's time

Solution analysis

We think of solutions that meet the criteria generated from the above exercises to understand the design needs. I locked on to a spool like mechanism that be enclosed and by spinning the spool the earphone wire can be wound.

Risks and benefits - benefit is that this design protects and organizes the earphone and it's small enough to fit into my pocket.

risk- the product I am thinking requires a sliding mechanism, I need to design a very good fabricating way for this mechanism. it might turn out to be a huge task, fine tuning and eating all dimensions right and for it to be

Fabduino

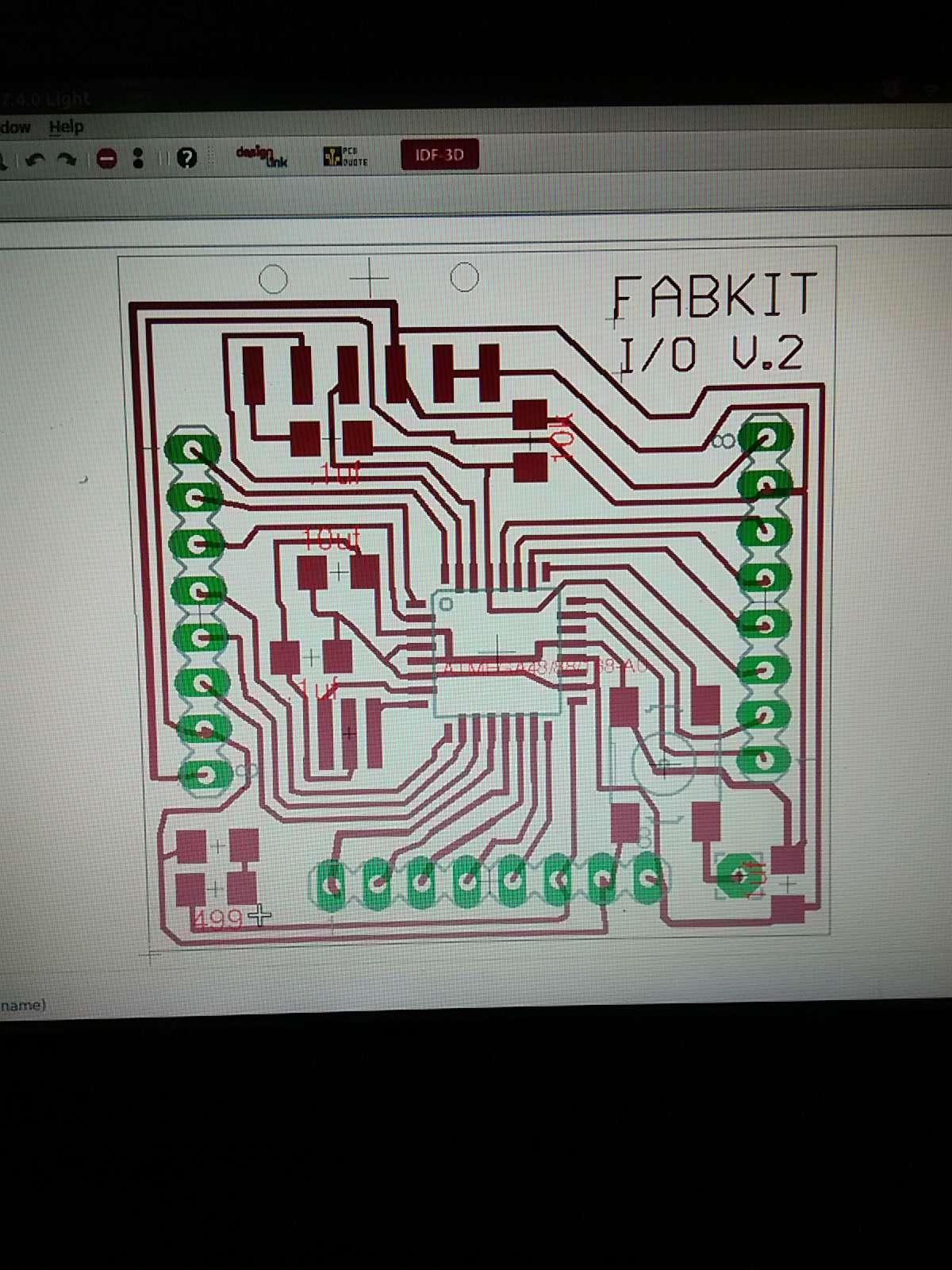

We tried to fabricate a Fabduino. Fabduino consists of atmel controller that can be programmed. It has far more pins, data storage than the attiny controller allowing us more freedom in coding and inputs and outputs. We downloaded the png for fabricating from the following links

What's different : as compared to attiny the atmel microcontroller has more leads and smaller gap between the lead and smaller leads and traces. It also accommodates holes so you'll have to download the holes png also. The png given by the site for holes is an inverted image, make sure you use invert function to set this right While milling. Use 1/32 bit to mill holes, same as outline. And make sure you mill the holes before milling the outline.

How?

We secure the microcontroller similar to attiny, by soldering two diagonals corners first.

Next instead of trying to solder each and every one to corresponding trace, we solder all pins together into one mass of lead on each of the 4 sides of the microcontroller.

All the pins are short now but we will remove all the mess at once using a copper braid.

On the bottom side of the microcontroller you can see that all mess has been removed and a clean soldering is achieved.

We had to get the component list and positions using eagle brd file using eagle software.