Molding Casting and Roland Modela

The basic idea for this session is to create an 3D object through computer and try to make it in machinable wax in such a way that a molding pattern is created directly from it. Roland modela will machine the wax. We will try to replicate this object by creating a silicone mold and later use the silicone mold to cast hard plastic into it.

3D printing is good for creating 3D form with interesting features and milling also can create 3D forms but these processes can't be used for mass manufacturing of products. Molding casting is a method by which things are mass-produced.

We have various smooth on resins to play with for molding and casting.

Smooth-on liquid rubber oomoo 25

Smooth-on liquid rubber oomoo 37

Smooth-on rubber mold-max 60

Smooth on liquid plastic

Update(15nov2015):We have only one type of hard plastic here and have a dozen of Oomoo 25 which had a shelf life of 4 months. All of them have gone to waste and are not setting. Oomoo 37 is setting without any problem the plastic is also good. Need to test mold max 60 which is used for metal casting.

The different numbers mean they have different physical properties such as setting time, hardness, safety precautions,shelf life etc.

These resins have a short life span(estimated 6months) and we seem to have a loads of them unused for a long time. We need to find a local supplier or a local alternative for smooth on because smooth on is a high quality product meant for artists and expensive. Here we are mostly interested in prototyping.

It is very important to read the instructions and product catalog to understand the chemicals better, how to handle them and to know what product suits your need.

The Smooth on here are the polyurethane plastic and silicone. The product come in two different part, Part A and Part B which are to be mixed in 1:1 ratio by volume and this mix will set in sometime. The setting time aka pot time, is the time you'll get to prepare it and work the material into the mold.

Notes: one part weighs more than the other dues to difference in densities .

Mixing: don't take the stick out once put in until mixing is done, don't mix in round motion or vigorously or else bubbles appear.

Mix in sideways left to right and vice versa motion. Mixing instruction are different for different material so read the manual for instructions.

Roland Modela

Roland modela is a mini desktop cnc milling machine which is popular for making milling traces on pcbs and for milling machinable wax.

it uses a type of mechanism that uses steel wire much like brake line wires to translate without an backlash.

Parts of roland modela

Roland modela milling kit

Scanning kit

Bits 1/64,1/32,1/16,1/8 and 0.01 mm from carbide.

Milling machinable wax in rolland

we tried to mill a machinable wax. we had a dark blue looking machinable wax. Interesting is that this machinable wax seemed to be a lower quality material. I think it might be more susceptible to melting rather than getting milled of. the properties can be improved by adding HDPE, a polythene that is reusable. HDPE is what the plastic covers in supermarkets and stores etc are made of.

Roland modela comes with a bed plate that has a grid pattern of 1cm. The zero of the grid places the spindle tool center at a grid origin. This is very helpful when placing the objects and knowing their positions. The bed can be removed easily and put back. Which gives the operator freedom of maintenance of the bed and also create replicas of the bed that can replace the bed. The metal bed is essential when milling a pcb. It offers good rigidity and flatness. This might not be required for milling machinable wax. Francisco suggested that a set of three bed plate for roland modela can be created so that when one person is done with machining the bed can be removed from him and another can easily switch the plate that he has already attached the another was block that needs machining.

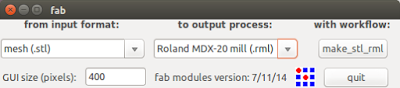

The paths for the roland, or the g code can be created by 2 methods using fab module.

Mesh(.stl)

or heightmap (.png)

Height map is a grayscale image that indicates intensity or the shade of gray as the height of the feature to be milled. A height map can be generated in antimony directly. It can also be generated by the fab module from an stl file by giving the input format as stl and output as png and following a process to create heightmap with parameters you need.

Assignment

1.To create a object in antimony such that a rubber resin can be poured into it directly and a negative replica can be created and later used to cast solid plastic parts.

2. Design roland modela bed plate from acrylic that can be used as an alternative for the metal bed that comes with modela. The grid should be engraved on it

Notes : Once the roland modela is set and connected by usb to the comp, you need to set permissions for writing directly to usb port. The rml files will be sent like this and directly to modela using fab modules. The permissions cabe set by running the following on the terminal

sudo chmod 666 /dev/ttyusb0

Only after this will a working communication channel will be established with modela and commands can be sent.

Preparations.

My model was inside a cavity of 50mmx50mm area and depth of 10mm. There was used partially used wax block of which we could salvage a good portion of a block that can be used for machining in modela.

Above, Nisha one my colleagues in prefab training is showing a demonstration of how to cut the wax properly. This is applicable for any other material to be used by this sawing machine.

Use goggles for eye protection

Carefully measure the length of the block you want to cut and make adjustment in the machine properly.

While cutting use left hand to push the material firmly to slide on the aluminium slide ruler as shown in the picture and use another block of object(a laser cut sample ply in the picture) to push the block through the saw.

Process

Fancisco gave me a file of outline of the bed plate of modela in svg format and I tried to add chamfers and the grid pattern on it using draftsight, a free for non commercial use clone of autocad. For this purpose I used different methods since svg cant be directly imported in to draftsight. I saved the svg to dxf format using inkscape. The final output was in dxf format and I also tried to export it as a svg file. The dxf file when opened in coral coral draw had missing features and the exported svg file had grouped some edges and the grid as one. This created a problem later.

Design:

Antimony

I created a simple torus shape inside a pocket of 40 by 40 by 15mm depth. The torus was 10 mm high allowing 5 mm clearance from the top.

Download files at

https://www.dropbox.com/s/9x87ewtc1wg5k8i/toruscast.sb?dl=0

https://www.dropbox.com/s/1nafkya6lgwraye/toruscast.stl?dl=0

https://www.dropbox.com/s/aog9ge7mzurond0/toruscast.png?dl=0

https://www.dropbox.com/s/i0dydpewrp67rdj/toruscast%20crop.png?dl=0

Toruscast by puneethrj on Sketchfab

Machinig parametersI used the heightmap to genearate the Gcode. The stl seems to take a lot of processing power and my system hang while processing stl.

But when you export a heightmap from antimony it gives you black border along with the actual height map so extra area and time is lost while milling that part hence I cropped the png and used it to generate the gcode. Unfortunaly this might not lead to precise results, my cropping might be unneccesary or might leave some parts uncropped. The cropping changes the dimensions of the png and it has to be scaled to original intended size adding to more errors.

BUG- sometime while handling a png file the such a generating a path or invert color the change is reflected directly on the actual file. due to this bug many time my pngs have gone completely black. This is a serious bug the developers have to work on to remove. No software will do such atrocious things to drawing you generated while eror in processing.

Roughing process -

z min: -15mm

process- roland 1/8 rough cut milling

Cut depth:1.6 mm

finishing process

z min: -15mm

process- roland 1/8 finishing cut

Cut depth:1 mm

Output: pictures cant be taken because the oomoo25 we used to pour in our molds didnt set and its mess to clean up now.

Laser

Design

You can download file at

https://www.dropbox.com/s/262r8leph3iri0r/bed_modela_polylines.dxf?dl=0

( On a totally unrelated note. We can see that an interesting pattern has emerged here formed from the fine dust that was splattered as a result of laser engraving of acrylic. The fine powder must have had some kind of static charge and some of them gathered more on top of the metal that is directly below in honey comb pattern.We can wipe it off easily and here you can see the grid pattern has emerged beautifully)

Problem

We noticed that the one particular edge of the acrylic wasn't cut at all. This happened due to the color of that being black.The problem was that that segment of line was somehow grouped with the internal grid. So changing the color of that segment usually led to change of color of the entire grid. To solve this I tried to create another line in red color and overlap it on that segment. The thinking was that the edge will get engraved as well as cut. But this didn't happen and the small segment got engraved only but not cut. Later Francisco used the dremel tool with circular blade to cut of the acrylic right at that part.

Conclusion:

Be careful while importing or exporting between different vector graphics software, you might see that the imported stuff is not the same as it looked in the software you used to create it. If doing this always recheck if all the features are as you intended. Dxf to svg especially, created had many issues like not importing splines or missing entities and random grouping.

Antimony is a great tool to design and a way to design cad fies.